Gray Construction - U1

Client: Gray Construction - U1

Location:

US East Coast

Project:

UPW System Mechanical installation

Application:

Mechanical Equipment Installation of Ultrapure Water Production System

Year Start:

2024

Scope of Services:

Balance-of-plant design and supply & Installation of Process Equipment and systems

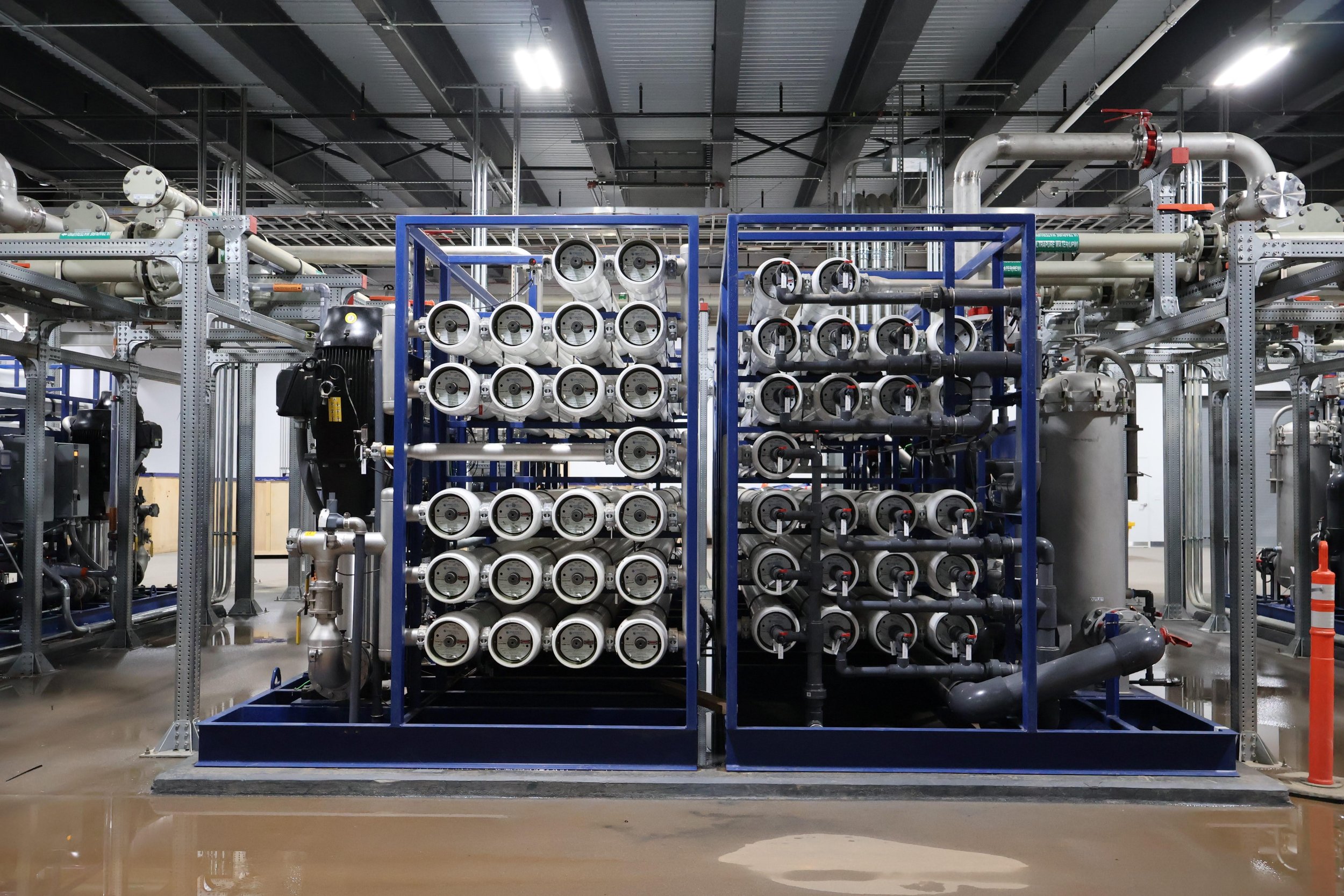

Executing mechanical installation and balance-of-plant integration for an ultrapure water production system supporting advanced solar panel manufacturing.

Executive Summary

For a large-scale solar panel manufacturing facility on the U.S. East Coast, Gray Construction required specialized mechanical execution to support the installation of an Ultrapure Water (UPW) production system critical to ingot, wafer, cell, and module manufacturing processes. The UPW system demanded precise mechanical integration, high-purity standards, and seamless coordination with ongoing facility construction to support reliable, continuous operations.

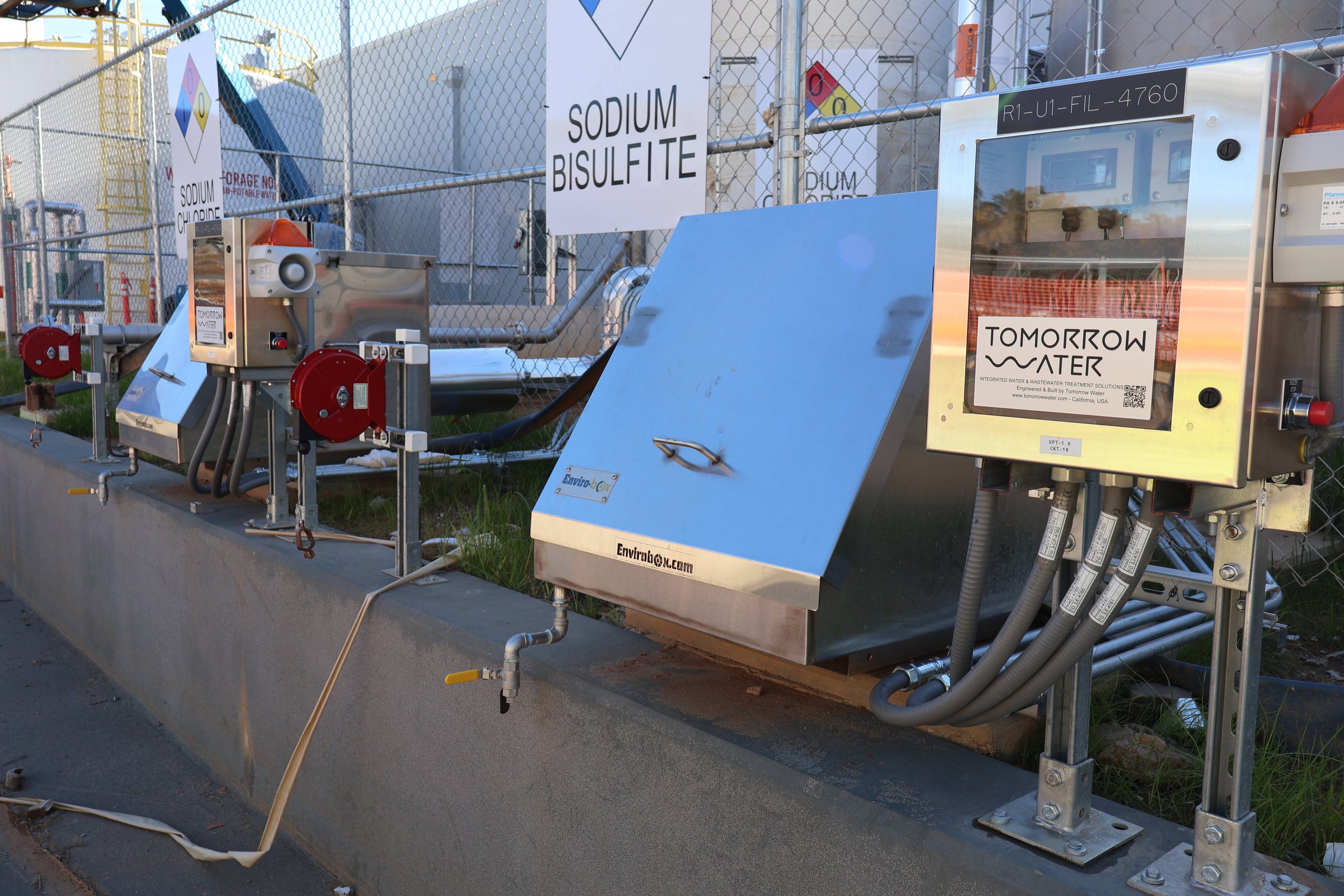

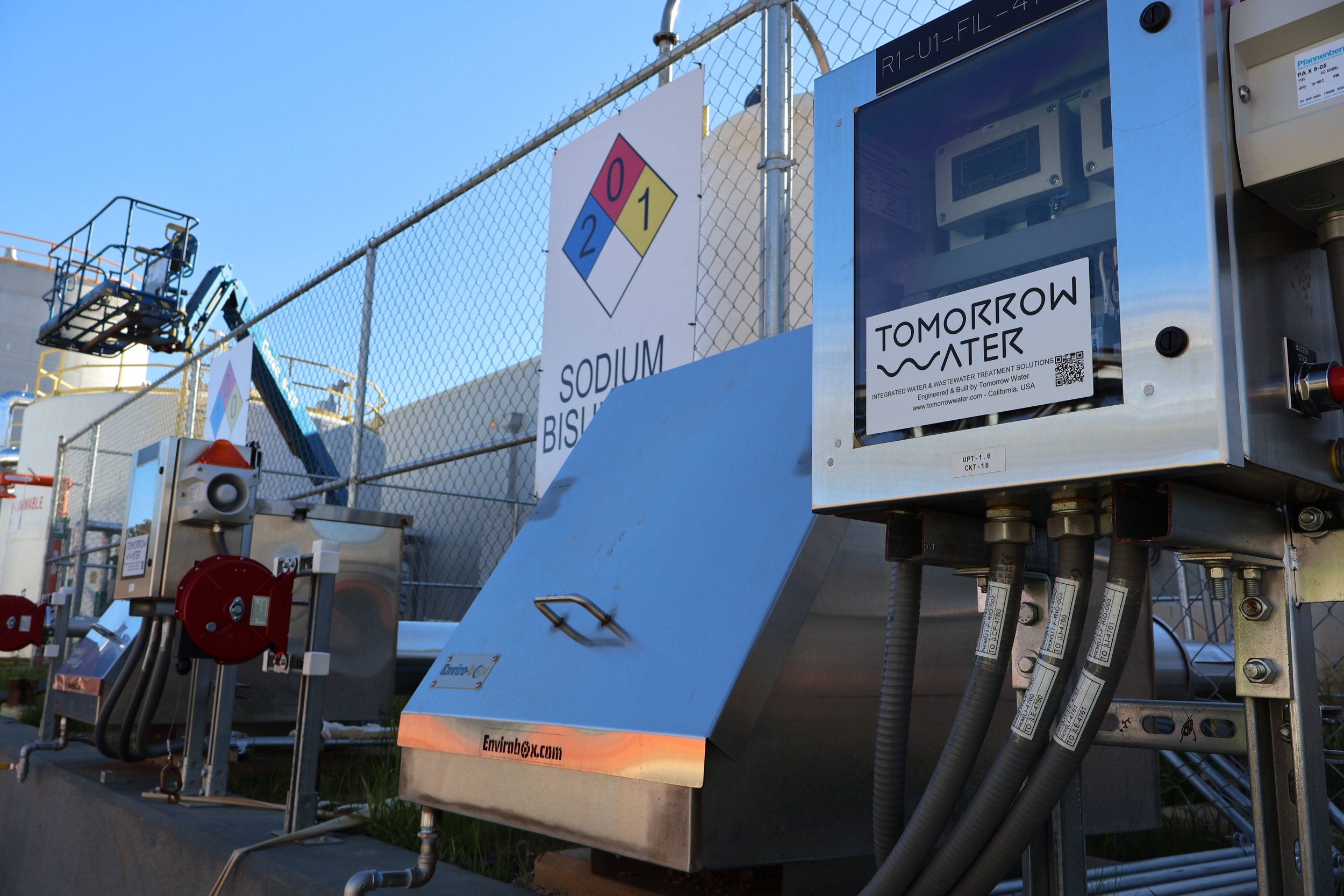

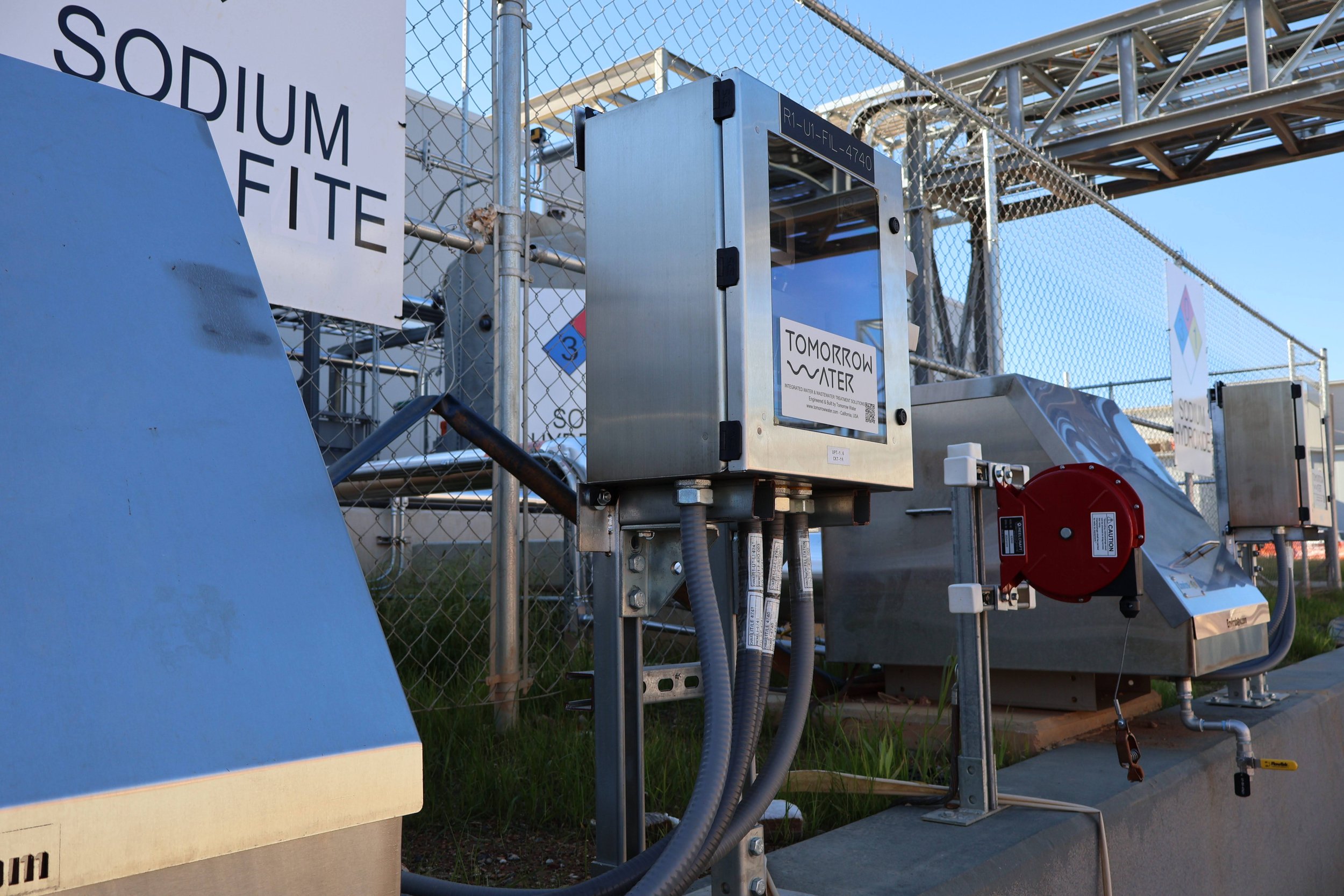

Tomorrow Water Actions and Scope

Tomorrow Water was responsible for balance-of-plant design and supply, along with mechanical installation of the Ultrapure Water (UPW) production system and associated process equipment. The scope included installation of major UPW process components, interconnecting piping, and mechanical systems, executed to meet stringent high-purity water standards.

High-purity PP-R piping systems were utilized throughout the UPW distribution network to prevent contamination and ensure material compatibility. Installation activities included controlled flushing, hydrostatic testing, and system cleaning protocols prior to commissioning. Extensive QA/QC procedures were implemented, including material traceability, weld and joint inspections, pressure testing verification, and cleanliness validation, to ensure the installed system achieved the conductivity and quality requirements necessary for UPW service. All work was closely coordinated with Gray Construction to maintain schedule alignment, installation quality, and readiness for startup.

Conclusion

Through disciplined mechanical execution and balance-of-plant integration, Tomorrow Water supported the successful deployment of a critical UPW production system for advanced solar manufacturing. The project demonstrates Tomorrow Water’s capability to deliver high-purity water infrastructure through precise installation, system integration, and construction-phase coordination ensuring performance, reliability, and long-term operability in demanding industrial environments.